Root Cause Analysis of Supply Chain Issues

In the manufacturing industry, supply chain issues can significantly impact production, costs, and customer satisfaction. Root cause analysis (RCA) is essential for understanding and addressing these challenges effectively. RCA helps identify the actual causes behind supply chain disruptions, leading to more effective and lasting solutions rather than merely addressing the symptoms. Using ProSolvr can enhance this analysis process.

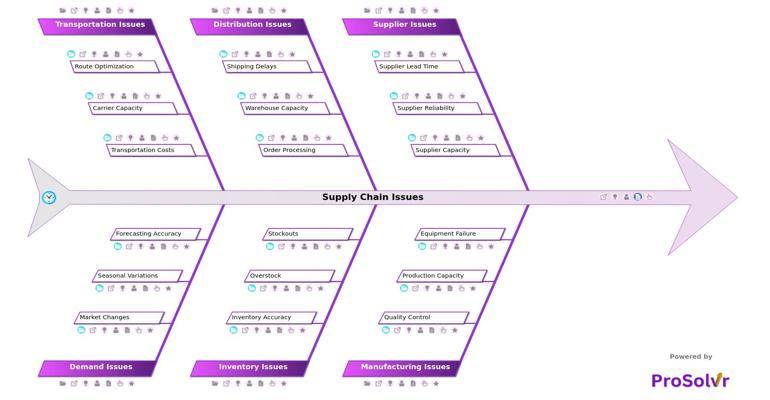

The fishbone diagram is a valuable tool for organizing potential causes of supply chain issues into major categories such as Supplier Issues, Manufacturing Issues, Distribution Issues, Inventory Issues, Transportation Issues, and Demand Issues. This structured visualization using an Ishikawa template helps teams systematically analyze each aspect of the supply chain. ProSolvr's Supply Chain Issues template is particularly useful in this context.

Visual root cause analysis, supported by fishbone templates, provides a clear and structured way to address complex supply chain challenges. By systematically identifying and addressing root causes, manufacturers can implement solutions that enhance operational efficiency, reduce costs, and improve customer satisfaction. ProSolvr encourages collaborative brainstorming sessions, fostering a comprehensive understanding of supply chain problems from various perspectives.

Operations managers can improve process efficiency, reduce delays, and streamline production with ProSolvr. Supply chain managers can identify bottlenecks, optimize logistics, and enhance supplier relationships. Inventory managers can improve accuracy and reduce stockouts or overstock situations. Additionally, logistics providers, distributors, retailers, consultants, and customers can benefit from the insights gained using ProSolvr’s templates. This comprehensive approach leads to more informed, data-driven decisions and better overall supply chain reliability.

The structured list above identifies critical operational challenges, offering a comprehensive overview of potential issues in supply chain management.

Who can learn from the Supply Chain Issues template?

- Quality tools like ProSolvr facilitate collaborative brainstorming sessions among quality control teams from various departments, ensuring a comprehensive understanding of problems from diverse perspectives.

- Operations managers can enhance process efficiency, minimize delays, and streamline production workflows.

- Supply chain managers benefit by identifying bottlenecks, optimizing logistics, and strengthening supplier relationships.

- Inventory managers can improve accuracy and mitigate issues like stockouts or overstock situations.

- Logistics providers can identify opportunities to enhance service levels, reduce lead times, and improve reliability.

- Distributors, retailers, supply chain consultants, B2B customers, and end consumers can also gain valuable insights from this template.

Why use this template?

- Understanding root causes enables decision-makers to implement strategic changes efficiently, supported by informed and data-driven decisions.

- Gen AI-powered root cause analysis helps develop both preventive actions (eliminating root causes before problems arise) and corrective actions (addressing existing issues effectively).

Use ProSolvr by smartQED to improve supply chain reliability, reduce production delays, and enhance overall efficiency in your organization.