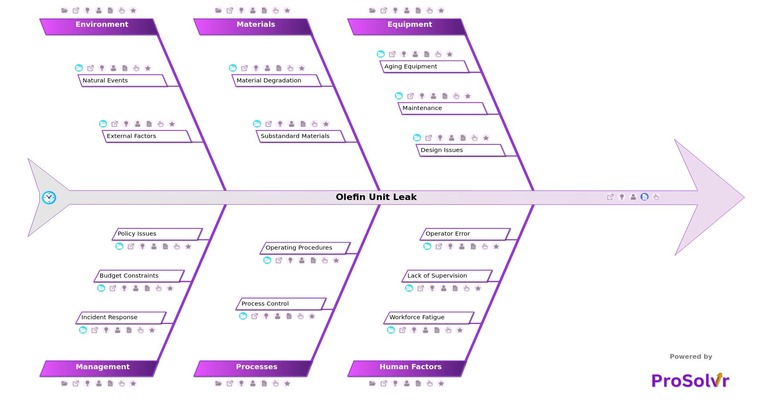

Root Cause Analysis of Olefin Unit Leak

The Olefin Unit leak at Haldia Petrochemicals in 2011 was a significant industrial incident that highlighted safety and operational challenges in petrochemical plants. Conducting a Root Cause Analysis (RCA) of this incident can provide invaluable insights to help the petrochemical industry address underlying issues rather than just treating the symptoms. By systematically investigating the causes of the leak, the analysis can identify the specific factors that led to the incident, whether they were related to equipment failure, human error, or process inadequacies.

The Olefin Unit, a critical part of the plant’s operations, is responsible for producing ethylene and propylene, which are essential feedstocks for various downstream products. The major leak in 2011 resulted in the release of hazardous gases, raising concerns about the safety protocols and the integrity of the equipment used at the plant.

Utilizing a visual tool like ProSolvr for RCA fosters a culture of continuous improvement within plants like Haldia Petrochemicals. Engaging different teams in the analysis and problem-solving process not only resolves the immediate issue but also strengthens internal processes and systems. This collaborative approach encourages knowledge sharing and improved communication across departments, leading to more robust operational practices. Lessons learned from the 2011 incident can serve as a valuable resource for training and informed future decision-making, further contributing to the plant's operational excellence.

Who can learn from the Olefin Unit Leak template?

- Plant Engineers and Maintenance Teams: Learn the importance of regular equipment inspections and early detection of potential issues.

- Safety and Risk Management Professionals: Refine risk assessment and emergency response strategies, focusing on robust safety protocols.

- Petrochemical Industry Leaders and Managers: Improve organizational practices, focusing on safety culture and continuous improvement.

Why use Olefin Unit Leak template?

Conducting a thorough Gen-AI powered RCA of the Olefin Unit leak, following Six Sigma principles, can yield significant financial and reputational benefits for plants like Haldia Petrochemicals. This proactive approach demonstrates to stakeholders, including regulatory bodies and the public, a commitment to maintaining high safety standards, helping to preserve the company's reputation and ensuring continued success in the competitive petrochemical industry.

Draft and create a template for problem analysis in ProSolvr by smartQED.