RCA of Ethylene Glycol leak

The 2014 Ethylene Glycol leak at Haldia Petrochemicals is a significant industrial incident involving the release of hazardous chemicals. While specific detailed reports on this incident may not be widely available, general practices in Root Cause Analysis (RCA) and information from similar industrial incidents can be applied to understand the likely causes and consequences.

Ethylene Glycol (C₂H₆O₂) is a colorless, odorless, sweet-tasting liquid commonly used as antifreeze and in the manufacture of polyester fibers and resins. It is toxic when ingested and can cause severe health issues such as kidney failure and metabolic acidosis. Prolonged exposure can lead to central nervous system depression and organ damage.

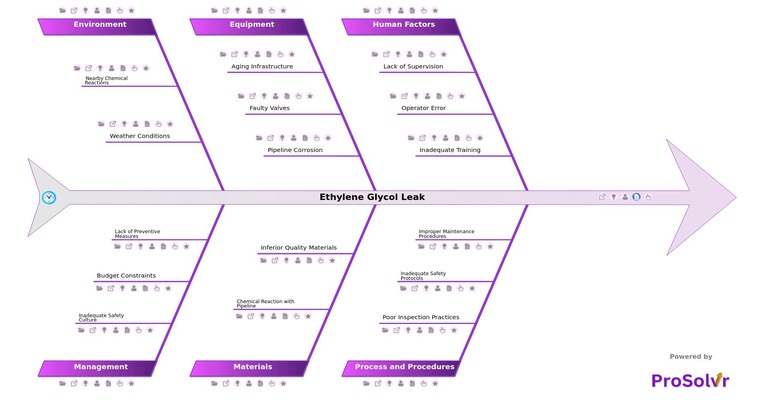

A Root Cause Analysis (RCA) using a fishbone diagram, also known as an Ishikawa or cause-and-effect diagram, is a powerful tool for systematically identifying the factors contributing to the Ethylene Glycol leak at Haldia Petrochemicals. This visual RCA tool, aligned with Six Sigma principles, helps categorize potential causes into key areas, allowing for a thorough examination of each to uncover underlying issues.

In this case, a Gen-AI powered RCA could highlight specific areas of concern. The analysis might focus on operational procedures, the condition of pipes, valves, and seals, and the training and safety protocols followed by plant personnel.

Who can learn from the Ethylene Glycol Leak template?

- Plant Operators and Engineers: Emphasize the importance of rigorous maintenance, process safety management, and continuous equipment monitoring.

- Safety Managers and Compliance Officers: Reinforce the need for strict adherence to safety protocols and regular audits.

- Government Regulators: Update and strengthen regulations to ensure adherence to high safety and environmental standards.

- Environmental Protection Agencies: Advocate for stringent controls, better pollution monitoring, and rapid response mechanisms.

- Engineering and Safety Education Programs: Incorporate this case into curricula to teach the importance of RCA, process safety, and the impacts of industrial accidents.

- Professional Training Providers: Develop training modules on leak prevention, emergency response, and best practices in maintenance and safety management.

Why use Ethylene Glycol Leak template?

ProSolvr, a quality tool, enables the identification of both immediate and systemic causes of the leak. This methodical approach aids in finding the root cause and guides the development of corrective and preventive actions to mitigate future risks, enhancing overall safety and reliability at the plant.

Similar incidents in the chemical and petrochemical industries often highlight the importance of preventive maintenance, regular inspections, and robust emergency response systems. Learning from these incidents can help in preventing future occurrences.

Draft and create a template for problem analysis in ProSolvr by smartQED.