Concorde Crash of Air France Flight 4590

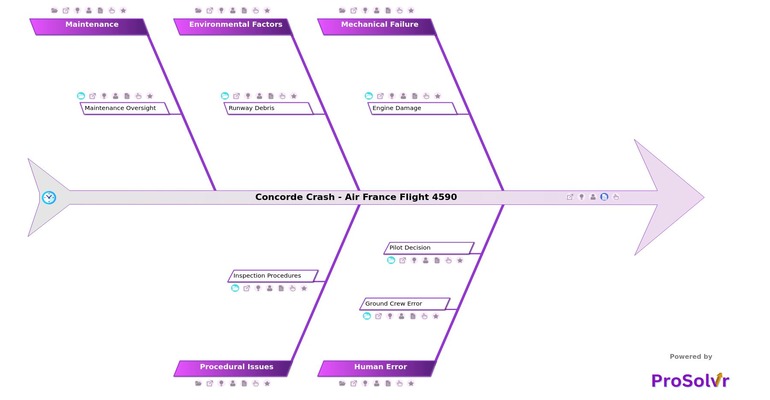

A fishbone diagram, also known as an Ishikawa diagram, can be highly effective for the root cause analysis (RCA), of complex incidents like the Concorde crash of Air France Flight 4590.

The crash of Air France Flight 4590 on 25th July, 2000 was precipitated by a chain of tragic events. As the aircraft sped down the runway during takeoff, it ran over a metal strip that had fallen from a preceding aircraft, a Continental Airlines DC-10. This strip caused a tire to burst, and debris from the tire rupture struck the underside of the Concorde's wing, leading to a puncture in the fuel tank. The resulting fuel leak ignited, causing a fire that compromised the aircraft's ability to climb and maintain altitude. Despite the crew's efforts to control the situation, the intense fire led to the loss of engine power, and the plane crashed into a hotel shortly after takeoff, killing all 109 people on board and four on the ground. This sequence of events highlighted significant vulnerabilities in runway debris management, aircraft design, and emergency response protocols.

This fishbone diagram, using the Six Sigma principles, helps organize potential causes of a problem in a structured manner, allowing investigators to systematically explore all contributing factors. By visually representing the relationship between the problem and its causes, the diagram helps identify not only the immediate causes but also the underlying issues that might have contributed to the accident.

In the case of the Concorde crash, such a visual RCA tool can categorize causes the effectively, providing a comprehensive overview of the multifaceted nature of the incident. Such a quality tool facilitates a thorough investigation by ensuring that all possible causes are considered. This includes examining technical failures such as the tire explosion caused by runway debris, human errors in maintenance and crew actions, environmental factors like runway conditions and weather, and organizational issues including inadequate safety procedures and regulatory oversight.

By breaking down the problem into these categories, investigators can delve deeper into each area, identify specific failures within each category, and understand how they interacted to result in the crash. This detailed analysis helps pinpoint not only what went wrong but also why it went wrong, which is crucial for developing effective preventive actions and corrective measures.

Who should use the Concorde Crash Air France 4590 template?

The Root Cause Analysis (RCA) of the Concorde crash provides valuable lessons for a wide range of stakeholders in the aviation and related industries.

Regulatory and Safety Training Organizations: Entities responsible for the training of aviation professionals, such as pilot schools and safety training institutions, can incorporate the lessons from the crash into their curricula. This can help future pilots, engineers, and safety officers understand the importance of following procedures, recognizing potential hazards, and responding appropriately to emergency situations.

By learning from the RCA of the Concorde crash, these categories of stakeholders can work towards preventing similar tragedies in the future and enhancing the overall safety of the aviation industry.

Why use the Concorde Crash Air France 4590 template?

Using quality and reliability tool like ProSolvr for creating a fishbone diagram aids in communication and collaboration among the investigative team and stakeholders. The visual nature of the Gen-AI powered RCA tool makes it easier to convey complex information clearly and concisely, ensuring that everyone involved has a shared understanding of the issues at hand. The diagram can help regulatory bodies, airline management, and maintenance crews can help illustrate the interconnected causes of the crash and highlight areas requiring improvement. This shared understanding is essential for implementing changes that can prevent future accidents, ultimately enhancing the overall safety and reliability of aviation operations.

Use ProSolvr by smartQED to create and customize your own templates for efficient root cause analysis of issues in your organization.

Create or customize your templates for problem analysis in ProSolvr by smartQED.

Curated from community experience and public sources: