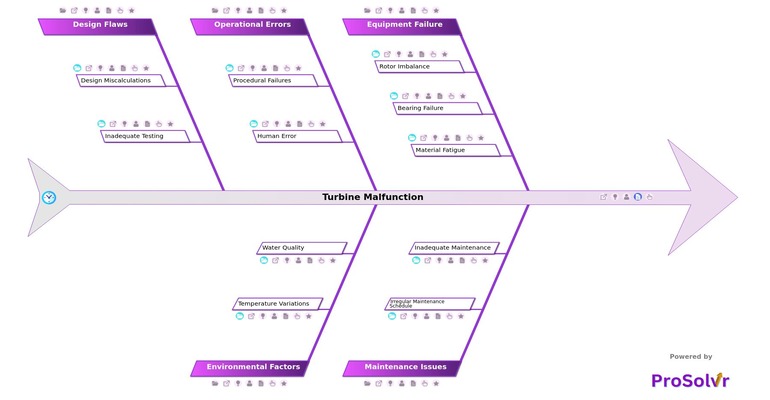

RCA of Turbine Malfunction in Hydel Power Plants

A fishbone template can be highly effective for conducting root cause analysis of particularly complex problems like turbine malfunctions in a hydel power plant. This template uses the Six Sigma principles and helps in systematically identifying potential causes behind the issue.

By visually mapping out all possible factors that might have contributed to the turbine malfunction, it ensures a thorough examination of all aspects of the operation, which can be crucial in a high-stakes environment like a hydro power facility. Using a visual tool allows the team to break down the problem into smaller, more manageable parts.

For instance, under the equipment category, the team can list specific components of the turbine that might be failing, such as bearings, blades, or the control system. Similarly, under the processes category, they can explore maintenance procedures, operational protocols, and training routines.

This systematic approach not only aids in identifying the immediate causes but also highlights systemic issues that might be overlooked when analyzing the problem in a less structured manner.

Who can learn from the Turbine Malfunction template?

The root cause analysis (RCA) of turbine malfunctions in a hydel power plant can provide valuable insights to a wide range of stakeholders.

- Plant Engineers and Technicians: Plant engineers and technicians can benefit directly from RCA by gaining a deeper understanding of the technical issues and potential failures that can affect turbine performance. This knowledge can help them improve maintenance practices, enhance troubleshooting skills, and implement more effective monitoring systems to prevent future malfunctions.

- Operational and Safety Management: Operational managers and safety officers can use the findings from RCA to refine operational protocols and safety procedures. By understanding the causes of turbine malfunctions, they can develop strategies to mitigate risks, ensure compliance with safety standards, and enhance overall plant safety. This can lead to better emergency preparedness and a reduction in the likelihood of accidents.

- Training and Development Teams: Training and development teams can leverage the insights from RCA to design more targeted and effective training programs for plant personnel. By incorporating lessons learned from past malfunctions into training curricula, they can ensure that staff is better equipped to handle similar issues in the future. This continuous learning approach helps in building a more skilled and knowledgeable workforce.

- Regulatory Bodies and Inspectors: Regulatory bodies and inspectors can use RCA outcomes to assess the plant's adherence to industry standards and regulations. The Gen-AI powered analysis can highlight areas where the plant may be falling short of compliance, prompting necessary corrective actions. Additionally, regulators can use this information to update and refine regulations to enhance safety and reliability in the industry by taking adequate preventive actions.

- Design and Manufacturing Teams: Teams involved in the design and manufacturing of turbine components can learn from the RCA to improve the reliability and durability of their products. Understanding the causes of malfunctions can guide design improvements, material selection, and quality control processes, ultimately leading to more robust turbine systems.

- Other Hydel Power Plants: Insights gained from the RCA can be shared across the hydro power industry, benefiting other plants with similar turbine systems. By disseminating lessons learned and best practices, the entire industry can improve its safety and operational standards, reducing the likelihood of similar malfunctions occurring elsewhere.

Why use Turbine Malfunction Template?

- The collaborative nature of using a fishbone diagram tool like ProSolvr fosters teamwork and ensures that insights from different stakeholders are considered. By involving diverse viewpoints, the team can uncover less obvious factors contributing to the turbine malfunction, such as human errors, communication breakdowns, or external environmental conditions. Ultimately, this comprehensive analysis helps in devising effective solutions and preventive measures, enhancing the reliability and safety of turbine operations in the hydel power plant.

Draft and create a template for problem analysis in ProSolvr by smartQED.