Root Cause Analysis of Takata Airbag Inflator Recall

Toyota's recall in 2024 due to Takata airbag inflator defects highlights the ongoing challenges faced by the automotive industry in ensuring Quality and Reliability. The recurrence of issues related to Takata airbag inflators underscores the importance of Root Cause Analysis (RCA) and Corrective and Preventive Actions (CAPA) in identifying and addressing systemic defects that compromise vehicle safety.

The Takata airbag inflator recall serves as a pivotal case study in the realm of Root Cause Analysis (RCA) and Corrective and Preventive Action (CAPA) within the automotive industry. This massive recall highlighted the critical importance of identifying underlying causes of safety defects and implementing effective corrective actions to mitigate risks and ensure product quality and reliability.

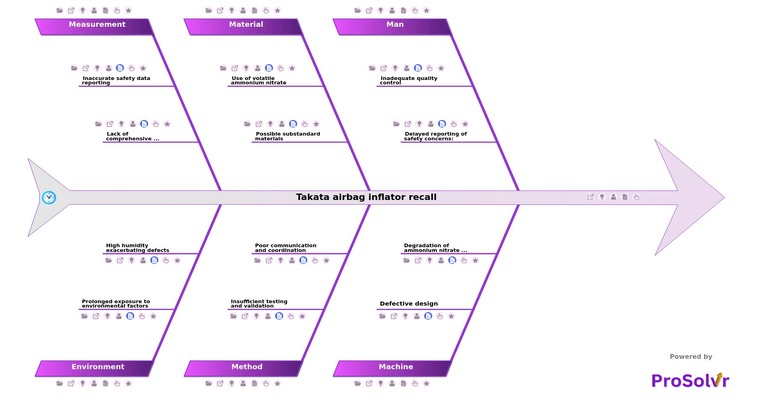

Root Cause Analysis (RCA) played a crucial role in uncovering the multifaceted issues contributing to the defective airbag inflators. The investigation revealed human errors in quality control, equipment defects, material vulnerabilities, methodological shortcomings, measurement inaccuracies, and environmental factors as key root causes of the safety issue. This comprehensive RCA approach enabled stakeholders to gain a deeper understanding of the systemic failures that led to the widespread defects.

Corrective and Preventive Action (CAPA) strategies were instrumental in addressing the identified root causes and implementing sustainable solutions to prevent future occurrences. Takata and automakers collaborated to develop and execute CAPA plans focused on enhancing quality control measures, rigorous testing protocols, transparent communication, and regulatory compliance. These targeted interventions aimed to rectify the underlying issues, improve product safety, rebuild consumer trust, and restore brand reputation.

Six Sigma methodologies were leveraged to streamline processes, reduce variability, and enhance overall product quality and reliability. By applying Six Sigma principles, organizations were able to identify inefficiencies, optimize operations, and implement data-driven improvements in manufacturing, testing, and quality assurance processes. This data-centric approach empowered stakeholders to make informed decisions, prioritize resources effectively, and drive continuous improvement initiatives to prevent similar quality issues in the future.

Quality and reliability became paramount considerations in the aftermath of the Takata airbag inflator recall. The incident underscored the need for rigorous quality assurance practices, robust manufacturing standards, and stringent regulatory compliance to safeguard consumer safety and uphold product integrity. Organizations across the automotive supply chain refocused their efforts on quality management systems, reliability engineering, and risk mitigation strategies to enhance product safety, meet regulatory requirements, and deliver superior value to customers.

The Takata airbag inflator recall underscored the critical importance of rigorous Root Cause Analysis (RCA), Corrective and Preventive Action (CAPA), and Six Sigma methodologies in ensuring product quality, reliability, and safety within the automotive industry. This transformative event served as a catalyst for organizational change, driving industry-wide improvements in quality management, risk mitigation, and regulatory compliance to safeguard consumer trust and uphold industry standards. Moving forward, these foundational principles will continue to shape and inform best practices, driving continuous improvement and innovation to deliver safer, more reliable vehicles to consumers worldwide.

Who should use the Takata Airbag Inflator Recall template?

- Automakers: Automotive manufacturers can utilize the recall template to understand the complexities involved in managing large-scale safety recalls, ensuring they have robust processes in place for identifying, addressing, and communicating safety issues effectively.

- Suppliers: Component suppliers can benefit from the template by gaining insights into the importance of quality control, material selection, and manufacturing processes to prevent defects and ensure product reliability.

- Regulatory Authorities: Regulatory agencies can use the recall template as a reference to assess compliance with safety standards, evaluate the adequacy of recall strategies, and monitor industry practices to protect consumer safety.

- Risk Management Professionals: Professionals responsible for risk management can leverage the template to develop and implement comprehensive risk assessment and mitigation strategies, focusing on proactive measures to prevent safety incidents and product failures.

- Quality Assurance Teams: Quality assurance teams can use the recall template to enhance their quality control measures, testing protocols, and inspection processes, ensuring products meet or exceed industry standards and customer expectations.

- Legal and Compliance Departments: Legal and compliance departments can refer to the recall template to understand the legal obligations and liabilities associated with product recalls, ensuring proper documentation, reporting, and adherence to regulatory requirements.

- Consumer Advocacy Groups: Consumer advocacy groups can utilize the recall template to educate consumers about their rights, raise awareness about safety issues, and monitor industry practices to hold companies accountable for ensuring product safety and quality.

Why use the Takata Airbag Inflator Recall template?

- Real-world Case Study: The Takata airbag inflator recall is a well-documented and widely recognized case study that provides a tangible example of the complexities and challenges associated with automotive safety and quality issues. Studying this real-world example offers valuable insights into the root causes, impact, and lessons learned from a significant industry crisis.

- Comprehensive Analysis: The Takata recall involves multiple layers of analysis, including human factors, equipment design, material selection, process methodologies, measurement accuracy, and environmental considerations. This multifaceted approach enables a comprehensive understanding of the interconnected factors influencing product quality, reliability, and safety.

- Learning Opportunities: By examining the Takata recall template, organizations and professionals can identify common pitfalls, best practices, and innovative solutions related to RCA, CAPA, Six Sigma, and quality management. This knowledge can inform future strategies, improve decision-making, and drive continuous improvement initiatives within their respective industries.

- Benchmarking and Comparison: The Takata recall serves as a benchmark for evaluating organizational performance, industry standards, and regulatory compliance in automotive safety and quality. By comparing and contrasting their practices with the Takata case study, organizations can identify gaps, prioritize areas for improvement, and set benchmarks for excellence in product quality and reliability.

- Risk Mitigation and Prevention: Utilizing the Takata recall template can help organizations proactively identify potential risks, vulnerabilities, and systemic issues within their products, processes, and supply chains. By applying the lessons learned from the Takata case, organizations can develop robust risk mitigation strategies, enhance quality assurance practices, and implement preventive measures to avoid similar crises in the future.