Root Cause Analysis of Poor Product Quality

Poor product quality poses a significant threat to the success and reputation of any business. Quality assurance is essential for maintaining customer trust, satisfaction, and brand credibility. Quality transcends price considerations and plays a pivotal role in ensuring customer loyalty and repeat business.

Various factors can influence product quality, including raw materials, worker skills, technology, equipment condition, working environment, and supply chain management. Identifying and addressing these quality issues effectively is crucial for businesses striving for excellence in their respective industries.

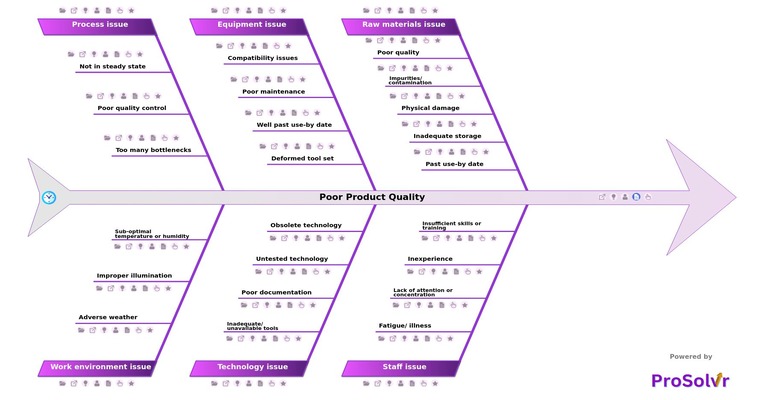

The fishbone diagram, a structured tool for root cause analysis, is instrumental in categorizing potential causes of poor product quality into distinct categories. Under the umbrella of raw materials, issues such as poor quality, impurities, physical damage, inadequate storage, and expired materials can compromise the final product's integrity and performance. Staff-related issues, including fatigue, lack of attention, inexperience, and inadequate training, can also contribute to quality deviations.

Equipment issues, such as compatibility problems, poor maintenance, outdated tools, and machinery malfunctions, further exacerbate quality concerns. Technological shortcomings, like inadequate software solutions, poor documentation, untested or obsolete technology, can negatively impact product quality and operational efficiency.

Process-related issues, such as inconsistent operations, poor quality control, bottlenecks, and inefficient workflows, can introduce variability, defects, and delays into the product development cycle. Additionally, work environment factors like adverse weather conditions, improper illumination, and sub-optimal temperature or humidity levels can adversely affect product quality and employee productivity.

Comprehensive quality management solutions tailored to address these challenges effectively are essential. The fishbone diagram template serves as a valuable guide, facilitating a hierarchical structure for organizing and analyzing the root causes of poor product quality. Whether you are looking to identify the reasons behind low-quality products, optimize manufacturing processes, or implement quality improvement initiatives, this visual and user-friendly template simplifies the analysis process, making it easier to understand, communicate, and resolve the underlying issues.

In conclusion, poor product quality is a multifaceted challenge that requires a holistic approach to problem-solving. By leveraging advanced tools and expertise, businesses can identify, address, and improve the various factors influencing product quality, ultimately enhancing customer satisfaction, driving operational excellence, and achieving sustainable growth.

Who should use the Poor Product Quality template?

- Product Managers: To identify and address quality issues affecting product performance and customer satisfaction.

- Quality Assurance Teams: To conduct root cause analysis and implement improvement strategies to enhance product quality.

- Manufacturing Engineers: To optimize manufacturing processes and reduce defects by identifying and resolving quality-related issues.

- Supply Chain Managers: To evaluate and improve the quality of raw materials and components sourced from suppliers.

- Operations Managers: To streamline operations and improve efficiency by addressing equipment and process-related quality issues.

- Training and Development Teams: To identify skill gaps and training needs among staff to improve product quality through better training programs.

- Senior Management: To gain insights into the factors affecting poor product quality and make informed decisions for strategic improvements.

- Consultants and Advisors: To guide businesses in identifying and resolving quality issues using a structured approach.

- Small Business Owners: To understand and improve product quality, ensuring customer satisfaction and business growth.

- Anyone Involved in Product Development: To ensure that quality is a priority at every stage of product development, from concept to delivery.

Why use the Poor Product Quality Template?

- Identify Root Causes: The template helps in identifying the root causes of poor product quality, enabling targeted solutions.

- Improve Customer Satisfaction: By addressing quality issues, businesses can enhance customer satisfaction and loyalty.

- Optimize Manufacturing Processes: Streamline manufacturing operations by identifying and resolving quality-related bottlenecks.

- Enhance Operational Efficiency: Improve overall efficiency by reducing defects, waste, and rework.

- Ensure Compliance: Meet industry standards and regulatory requirements by maintaining high-quality standards.

- Reduce Costs: By preventing defects and improving processes, businesses can reduce costs associated with quality issues.

- Drive Business Growth: Enhance product quality to attract new customers, retain existing ones, and drive business growth.

- Empower Stakeholders: Provide teams with a structured approach to quality management, fostering collaboration and accountability.

- Make Informed Decisions: Gain insights into quality metrics and performance indicators to make data-driven decisions.

- Continuous Improvement: Foster a culture of continuous improvement by regularly evaluating and optimizing product quality.

The Poor Product Quality template serves as a comprehensive tool to diagnose issues, plan improvements, and implement strategies that can lead to significant enhancements in product quality and customer satisfaction.

Draft and create a template for problem analysis in ProSolvr by smartQED.

Curated from community experience and public sources: