RCA of Aircraft Maintenance Failure

Aircraft maintenance failure is a critical issue that directly impacts the safety of crew members and passengers. The maintenance process is complex, comprehensive, and continuous, encompassing activities such as Servicing, Maintenance Repair and Overhaul (SMRO). Given the significance of these processes, close attention from oversight authorities is crucial. Outsourcing such intricate areas to external parties can introduce various risk factors, making it an unwise policy. Therefore, it is essential to conduct regular inspections and maintenance on the entire aircraft, adhering to international standards mandated by oversight authorities such as CAA, FAA, JAA, CEMILAC, and RCI, among others.

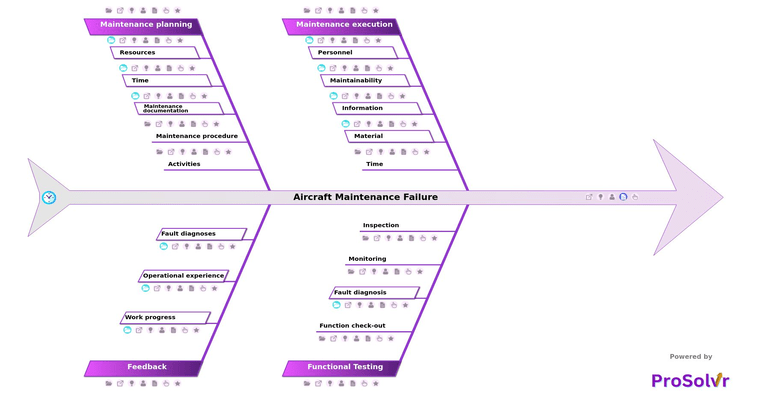

Contributing factors to effective maintenance include defining the problem accurately, operational excellence, and identifying the root causes of issues through methods like root cause analysis (RCA). Root cause analysis methods, such as the Ishikawa diagram or fishbone diagram, help in causal factor analysis, addressing the real root of the problem rather than just the symptoms. Failure mode and effects analysis (FMEA) is another valuable tool in the problem-solving process, allowing for a systematic approach to identifying potential failure modes and their effects.

Continuous monitoring of assemblies, sub-assemblies, Rotables, Shelf-life-parts, and Line Replacement Units should be conducted after a specified period or flight hours/flight cycles. Certain parts require replacement due to shelf life or flight cycle expiry at predetermined intervals. Additionally, cleaning aircraft and avionics components is also an integral part of the maintenance process. By employing root cause analysis tools and adhering to established business processes, we can ensure the ongoing safety and reliability of aircraft operations.

Analyzing the fundamental causes using a structured fishbone diagram aids in comprehending the underlying reasons behind Aircraft Maintenance Failures. Prevention being superior to cure, outlined above are the benefits of employing this template within the aircraft industry. It enables proactive measures to be contemplated, averting mishaps or accidents before they occur.

Who should use the Aircraft Maintenance Failure template?

Why use this template?

Curated from community experience and public sources: