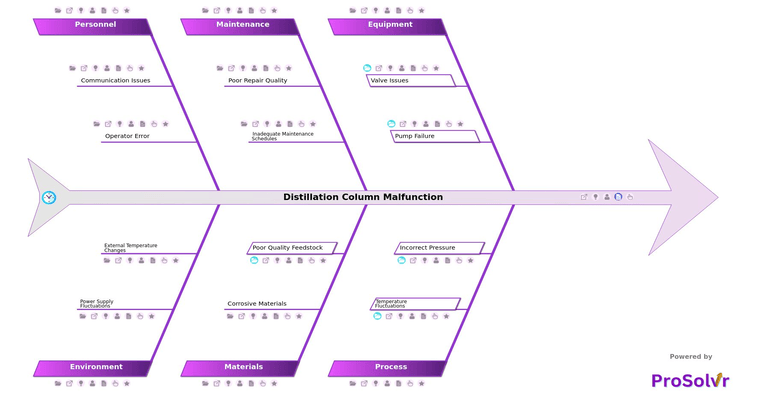

RCA of Distillation Column Malfunction

Distillation columns are essential in petrochemical plants for separating mixtures based on their boiling points. Root Cause Analysis (RCA) with a fishbone diagram, or Ishikawa diagram, is a valuable method for tackling distillation column malfunctions. This tool helps teams systematically identify and categorize potential causes of the malfunction across various areas.

Malfunctions in distillation columns can severely disrupt the production process, leading to inefficiencies, safety hazards, and potential shutdowns. Common issues include problems with equipment, such as valve issues (incorrect valve size, stuck or jammed valves), pump failure (motor burnout, seal leaks), and temperature fluctuations. In addition, incorrect pressure settings or malfunctioning pressure sensors can cause significant process disruptions. These problems may arise from equipment wear and tear, operational errors, variations in feed quality, or inadequate maintenance schedules. Addressing these root causes is crucial for maintaining plant reliability and improving overall efficiency.

Using a fishbone diagram in the RCA process enables teams to develop targeted corrective and preventive actions. For instance, if fouling is identified as a cause, teams might revise maintenance schedules or improve feedstock pre-treatment. If operator error is the issue, additional training or updated procedures may be necessary. This structured approach not only resolves the current malfunction but also helps prevent future occurrences, thereby improving overall plant reliability and efficiency.

Who can benefit from the Distillation Column Malfunction template?

Root Cause Analysis (RCA) of Distillation Column Malfunction provide valuable insights for various stakeholder

- Operations and Production Teams: They handle the distillation columns directly and can use the RCA template to understand root causes of malfunctions, improving operational procedures.

- Maintenance and Engineering Teams: Responsible for equipment upkeep and repair, they can use RCA insights to enhance maintenance schedules and address equipment-related issues more effectively.

- Process Engineers: They can optimize process parameters by learning from RCA, ensuring that temperature, pressure, and other critical factors are maintained within optimal ranges to prevent malfunctions.

- Safety and Compliance Officers: They can identify and mitigate safety risks related to distillation column malfunctions using the RCA template, ensuring compliance with safety standards and regulations.

- Quality Assurance Teams: They can understand how poor-quality feedstock or materials contribute to malfunctions, leading to better quality control measures in procurement and production processes.

- Training and Development Managers: They can use RCA findings to design targeted training programs for operators and other personnel, reducing human error and improving overall performance.

Why use this template?

Using Root Cause Analysis (RCA) for distillation column malfunctions offers significant benefits by providing a systematic approach to problem-solving. Gen-AI powered RCA identifies the underlying causes of malfunctions rather than just addressing symptoms, leading to more effective and lasting solutions. By analyzing factors such as equipment failures, process deviations, material quality issues, and human errors, RCA helps implement targeted corrective and preventive actions. This approach minimizes the likelihood of future malfunctions and enhances operational efficiency, safety, and reliability within the plant.

Draft and create a template for problem analysis in ProSolvr by smartQED.